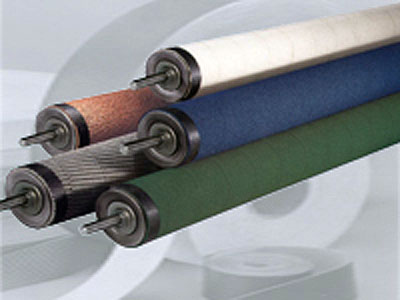

Thanks to the application of a proper covering the friction rate between the belt and the drum is increasing. This is the easiest and fastest way for sliding reduction and circuit force increase, therby reduction of belt tensioning. Noppen covering can be used for tracking of PTFE coated fiberglass mesh belt. In our offer we have self-adhesive and without glue coverings in three standard widths: 50mm, 70mm, 100mm, all in different colours and top surface structures. The coverings might come in oil resistant versions and are available generally in 50 mb or 100 mb rolls, per your inquiry. In case of in stock coverings it is available to purchase smaller quantities.

Synthetic rubber heat resistant up to 120°C

Natural rubber heat resistant up to 100°C

PU covering heat resistant up to 80°C

PVC covering heat resistant up to 80°C

Covernigs made of above mentioned materials are heat resistant in the range of 80oC to 160oC , and silicone even up 220oC:

- K – synthetic rubber 100-120oC

- KAS – synthetic antistatic rubber 110oC

- N – natural rubber 100oC

- P – PCV 70-80-90oC

- SP – special PVC/LAMINEX 80oC

- PU – polyurethane 80oC

- C – cork and rubber 90oC

- F – nylon 80oC

- S – silicone 150-220oC

- SE – synthetic elastometer

- SF – synthetic felt 100oC

- WF – cotton felt 100oC

- SB – flock (velour)

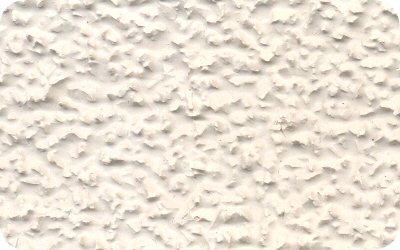

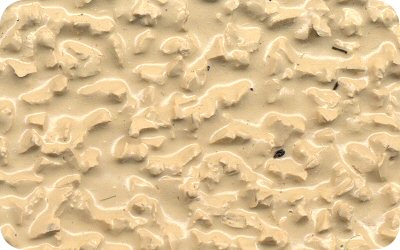

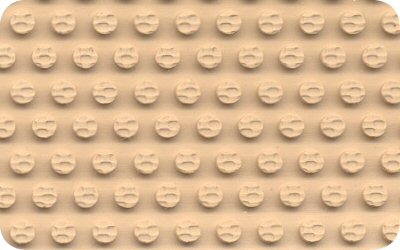

The coverings come in different colours (white, grey, natural, blue, black) and have various textures:

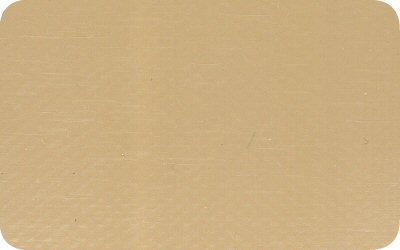

- fine (without any texture)

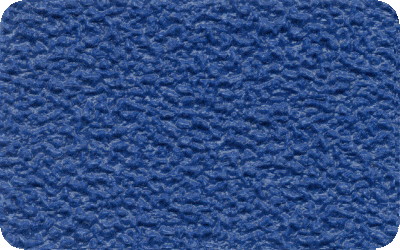

- soft/rought lattice pattern

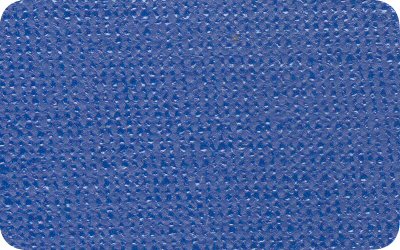

- fine/rough textile pattern

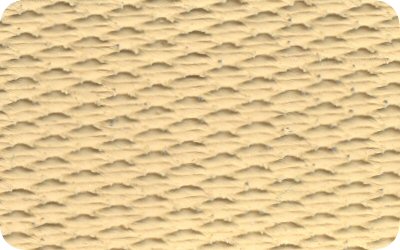

- ping-pong pallets pattern

- grip pattern

We have also special endless veneers in our range of products such as:

Thermo- retractable felt sleeves used for rollers in washing, backing or other industries. After fitting on the sleeve, the roller needs to be poured with hot water and then the felt starts to shrink under the temperature. When drying finishes the covering fits tightly to the drum.

Please pay attention to precise degreasing of the pulley and it’s careful performance. The contact area of warps may be affected to mechanical damage. No free spaces should appear during sticking of each wrap. This condition needs to be keept for proper working, otherwise the covering will impact the belt, same way as screw thread and couse belt’s transverse sliding.

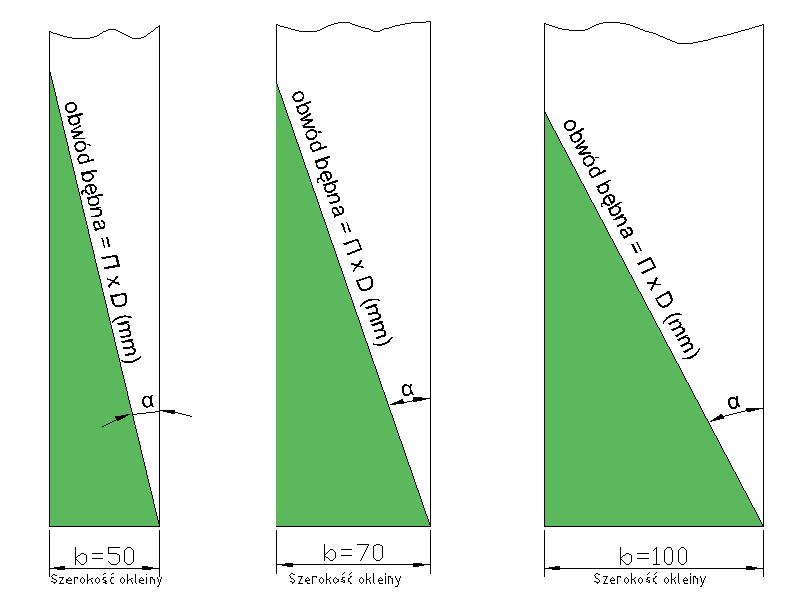

The smaller pulley diameter is , the smaller covering’s width should be, this is a rule to keep the spiral angle as acute as possible.

Calculating of veneer quantity necessary for roller covering:

Step 1. Calculating of cutting length for roller covering:

Ø drum (mm) x π

Example cutting length for drum of 200mm diameter is 628mm

Before winding of covering it is necessary to cut off the coloured area. Please secure the final warp with insulating tape.

Step 2. Calculation of the total length of veneer:

(Ø of drum (mm) x π x roller’s lenght (mm)) / (veneer’s width (mm)) + π x d

Example: Calculation of veneer lenght for a drum with 200mm diameter and 1500mm lenght, veneer’s width is 50mm according to following formula:

(200 mm x 3,14 x 1500 mm) / 50 mm + 3,14 x 200 mm = 18840 mm + 628 mm = ca19500 mm