| Type | Belt thickness[mm] | Assembly |

|---|---|---|

| ANKER (wire) | up to 10 | special installation tooling + chuck |

| ALLIGATOR, SL (plate) | 1,5- 6,4 | special installation tooling |

| NIEKA (plate) | up to 18 | self-assemble using rivets and a hammer |

Mechanical fasters allow to minimalize the machine downtime by reducing the time of belt assembly with no need to conveyor disassembling or when due to technical issues there is no possibility to fit the belt that is already closed or need to spliced.

Dobór złączek mechanicznych dokonuje się na podstawie następujących danych:

/For selection of proper fastner below data are basic:

- minimum pulley diameters

- thickness and durability of belt

- type of material transportated on belt

The great selection of mechanical fastners enables to use them almost for every industry for belts of different thicknesses and widths.

Fastners can be made of galvanized or stainless steel and plastic.

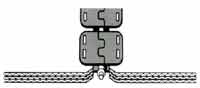

Apart from regular mechanical fastenings – hidden fastening installation are available. They are used when the material transported on belt can not meet the mechanical fastner (fastner damage risk) or when it is required that the transportation side must to be even.

Most commonon used mechanical fastners:

|

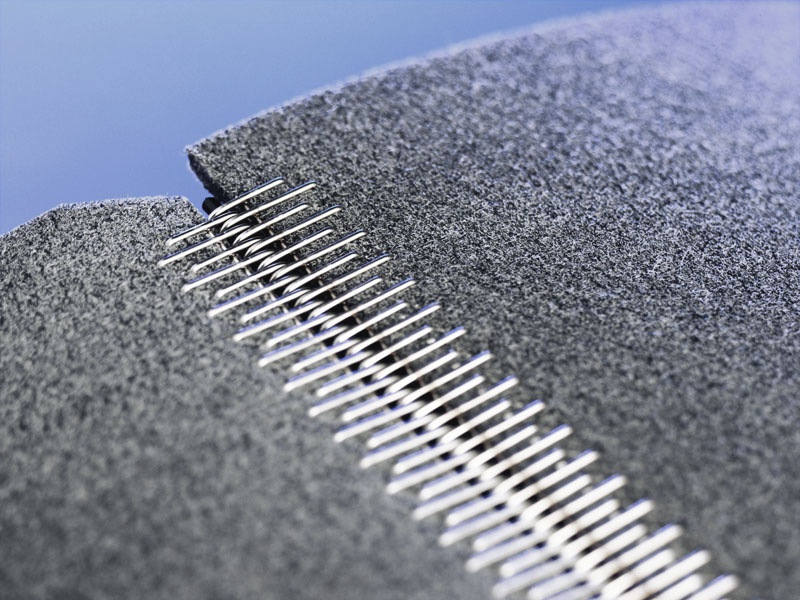

- złączki z drutu stalowego ocynkowanego lub nierdzewnego (typ ANKER)/ wire fasters made of zink coated steel or stainless steel

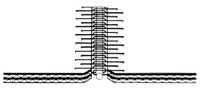

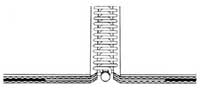

- złączki płytkowe (typ NIEKA, ALLIGATOR, SL) wersja za stali ocynkowanej i nierdzewnej oraz tworzywa (ALLIGATOR)/ plate fastners (NIEKA, ALLIGATOR, SL types) made of zink coated and stainless steel or plastic

- złączki spiralne z tworzywa/ spiral plastic fasteners

- złączki do taśm elewatorowych/ fastners for elevator belts

- złączki naprawcze/ fixing fasteners