WELDING ( FLEXPROOF )

|

Z splice jointing – flexible (EF)

even thickness , standard use for 1 and 2 play belts, specifically for knife-edges.

|

|

Z splice jointing– stepped (EFX)

flexible and of even thickness, hard operation conditions (dirt on drumms), specifically for 2 and 3 ply belts.

|

GLUING ( THERMOFIX ) – straight or inclined for PVC or PU belts

|

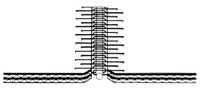

Wedge splice (ET)

for multiply belt types and NOVO (Fleece) types

|

|

Stepped overlap splice

specifically for 2 or 3 ply belts with duroplast UH, VH, U3 covers

|

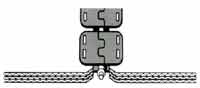

MECHANICAL ( złączki mechaniczne: Aligator, Anker, Nieka )/ mechanical fasteners: Aligator, Anker, Nieka

|

- złączki z drutu/ wire fasteners made of zinc coated or stainless steel (ANKER type)

- złączki płytkowe/ plate fasteners (NIEKA, ALIGATOR, SL types ) made of zinc coated or stainless steel

- plastic spiral fasteners

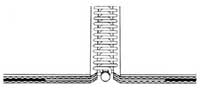

TAŚM ELEWATOROWYCH/Elevator belt jointing (overlap)

Overlap jointings are applicated for thin elevator belts that have few number of plies. The overlap lenght depends on belt load and may contain from 2 to 6 elevator buckets.

For double overlap jointing apply same type of belt for the overlay.

|

|

| Single overlap | Double overlap |

Important!

- After first 24 hour you should check the splicing area.

- The splicing area should be examinated every 4 weeks for safety reasons, due to being impacted by various forces.

- Enitra and elevator belt manufacturers recommend to use mechanical fasteners.