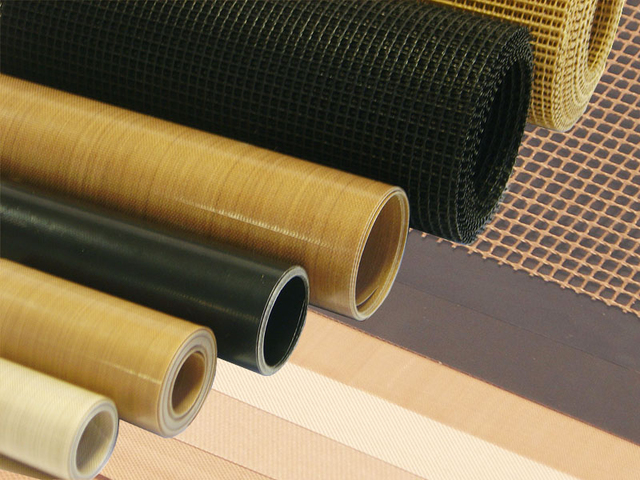

Since many years Enitra spetializes in fiberglass and kevlar PTFE coated belts and mesh confictionery.

Except for standard belts we have special versions available in our offer, such as belts with steel noppen tracking of various diameters and with kevlar rope.

We are manufacturing belts according to customized drawings.

Właściwości taśm z PTFE i siatek pokrytych PTFE (politetrafluoroetylen)

- temperature resistance – 150 up to + 260oC for continuous working

- low friction index

- great anti-adhasion properties

- high chemical resistance

- antistatic (only black belts and meshes)

- great diaelectric resistance (honey colour belts)

- air transmissive (mesh)

- have great insulation properties

- easy to wash up

- hygienic, siutable for food application

- hydrophobic (do not soak water)

- flame retardant

- UV light and weather conditions resistant

- wear resistant

- great heat conduction

- low electric losses

- tear resistant

- elongation resistant

- stabile dimensions

- cut resistant

- flexible

- microwave transmissive

A variety of meshes and their confectioning posibilities allow to applicate such meshes for almost all industries.

The most popular industrial applications:

- food industry – cake baking and becon/meat grilling

- wood processing – resin hardening and laminate covering of wooden elements and MDF (furniture manufacturing)

- rubber processing – rubber seal extruding

- clothing industry – fabric and stiffener melting

and

- termal fabric splicing

- toilet paper and hand towel packaging welders

- silicone curtain gor heating tunnels

- product packaging in vacuum tunnels

- printed paper drying

- production and hardening of plastic foam

- PVC widnow profile welders

- printed fabrics drying

- carpet botom side covering and floor-covering production

Special performings

- aramide / kevlar mesh belts coverd with PTFE

- silicone curtains (white/red)

- PTFE seals, temperature resistance from – 240 up to + 270 C

- silicone sponge COHRlastic

- rollers and discs

- self-adhesive sled run PE belts

Fiberglass belts

PTFE coated fiberglass belts came in antistatic and non-antistatic versions, in thickness from 0,07 mm up to 0,75 mm, as self-adhesive and without glue belts. They are available open and spliced using different fastening methods.

NON-ANTISTATIC and ANTISTATIC

- double coated PTFE

- self-adhesive – standard thickness range form 0,07 up to 0,75 mm

- (non-standard thickness available)

Belt splicing types

MECHANICAL

- ANKER type fastener

- BULLNOSE plastic fastener

- PEEK 6/8 spiral fastener

- knuckle type fastener

NON-MECHANICAL

- ET- overlap splicing

- EST- overlap crosswise splicing

- ETS – overlap splicing (with grinded ends)

- EF – Flexproof (zig-zag)

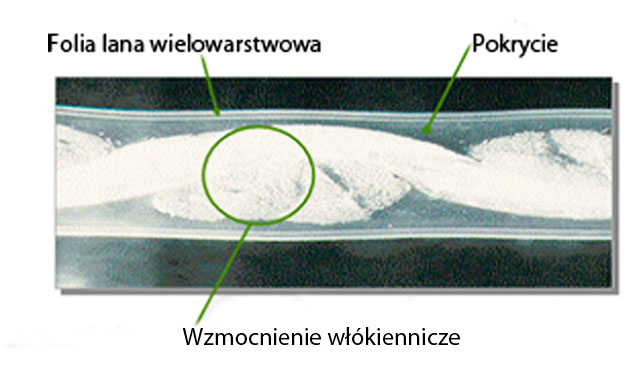

Fiberglass belts coated with foil

CHEMLAM belts

CHEMLAM belts with thick PTFE ply, smoothness siut perfectly for chemical industry, plastic processing and food industry.

- available thicknesses from 0,11 up to 0,41 mm

- perfect mechanical properties

- non-compatible material splicing/joining

- surface free of cuts and holes

- low chemical permeation

- low grease permeation

- easy to keep clean – no free spaces for bakteria accumulation

Fiberglass PTFE coated mesh belts

Fiberglass or kevlar PTFE coated mesh belts are available antistatic (black) and non-antistatic (honey).

They are of great heat nad air permeability for easier working in drying tunnels in textile manufacturing.

Mesh belts are available in a variety of dimensions. Standard width is max 4 mb, the length depends on Customer requirement.

Meshes come with edge protectioning agains fraying nad cracking. Mesh belts are in most of cases sold spliced using mechanical fastener.

Standard dimensions available (ANTISTATIC AND NON-ANTISTATIC)

- eyelet 4 x 4 mm

- eyelet 6 x 6 mm

- eyelet 8 x 8 mm

Basic requirements for fiberglass PTFE coated belt application

- minimum pulley diameter of 100 mm

- pulleys with rubber friction coverings (at least on drive pulley).