Nadella linear systems stands for transferring production automation on more heavier and cumbersome devices and also those once that need accurate andlong-lasting running. A variety of rails, guids and rolls made of best alloy and steel (i.a. bearing steel), processed by cold drawing, anodizing, grinding, sandblasting and induction hardening retaining the minimum hardness of 58 HRC. Those allow long-lasting accurate usage in a special transportation areas to all users. Rails and linear system elements enable working in oxidative, corroding environment of height temperatures up to + 120 o C (per request).

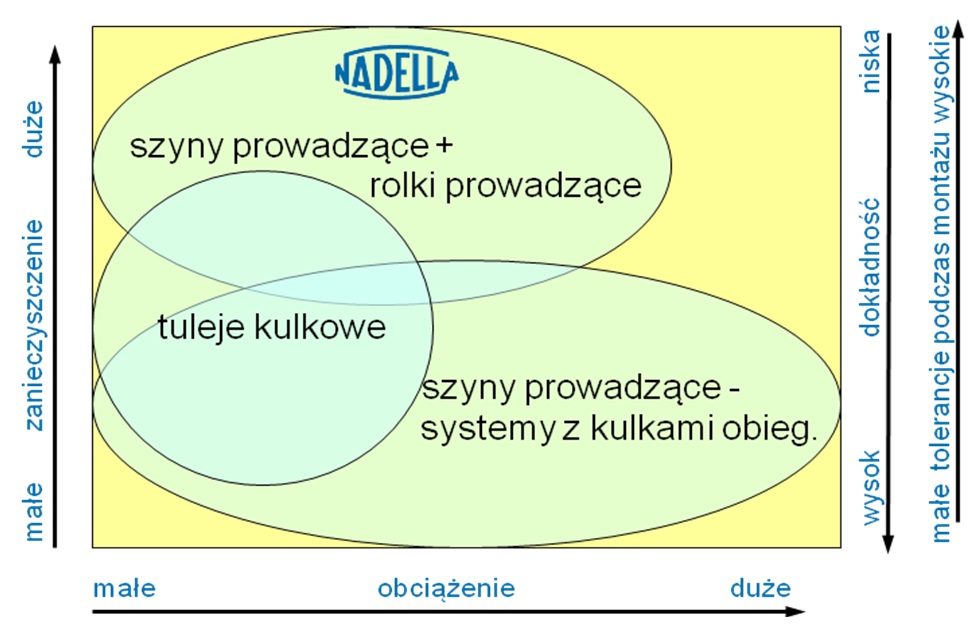

Nadella linear guides are used for all standard heavy/medium/light loads applications, with high speed and in contaminated enviroment, where assembly high tolerances are required (see chart):

All elements are manufactured of greatest accuracy and length of tolerance from +/- 0,5 mm to +/- 2,5 mm depending form section’s length, for more details please see page 6. Giudes are provided in one piece up to 5000 mm with standard borings or according to boring layout drawing given by the Customer. Nadella offers a variety of rolls to meet different technical and economic requirements.All guide rollers are produced in concentric and accentric design to enable firmed assembly. For bearing protection against dust and grease leaks, the rolls are equipped with special seals.

For more technical data, calculation and assortment please visit website: www.nadella.de

Nadella linear system can be applicated to machines such as:

- gas cutting machines

- machines for stone and ceramic processing

- device and tool relocationing machines

- textile machines

- automated warehouse

- packaging machines

- injectioning and foundring machines

- soundproof door

- precision tools

and more applications, where precision and reliability in motion is required.

Nadella offers also telescopic slides.

For more information please go to http://issuu.com/nadella/docs/tl2011de_web?mode=a_p