Poly V belts give mainly drive solution, but sometimes also are used for transportation. Materials used for Poly V belt manufacturing are of polibutadiene group of materials.

Our main supplier of Poly-V belts is HUTCHINSON® company.

Our Poly V belts have H, J L profiles. Profiles M and K are also available but per special request. Additionally we offer Poly V pulleys, that are not a standard group of products and therefore need to be discussed with our specialists.

Poly V belts cover a wide range of application and are ideal where you have high torque drives and small pulley diameters. They can be used on smooth pulleys due to avoiding the belt to jump off pulley.

The application of overlays allows to use the belt as a drive and transportation element.

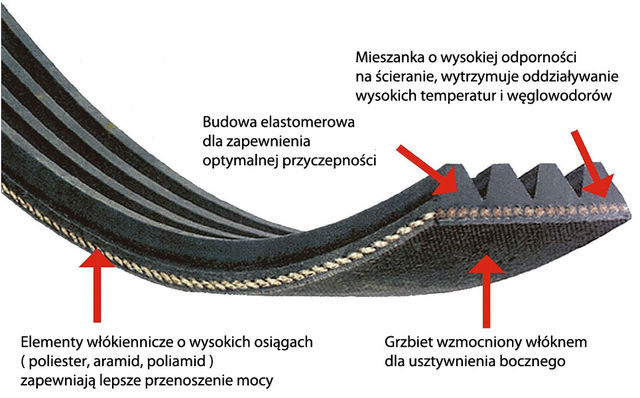

Poly V belt structure enables to use those belts for shafts of lower precision. Poly V belts are resistant to elongation, oil and temperatures.

Poly V belts are used for drive and conveyor elements for heavy industry machines like:

- press machines

- grinding machines

- wood processing machines

- conveyor belt drives

- roller conveyor drives

Poly V belt structure

Advantages:

- high power transmission range up to 600 kW,

- improved transmission ratio 1:60 (V belts 1:20),

- working on small pulley diameters,

- only one Poly V belt for transmission,

- smooth running drive system with low vibration

- constant tension rate,

- brak efektu trzepotania pasa,

- reduced noise level

- optimum contact surface area,

- increased lifespan,

- reduced maintenance costs

Types of Poly V belts and their properties:

| Profile PH | Profile PJ | Profile PK | Profile PL | Profile PM | |

|---|---|---|---|---|---|

| Ribs pitch | 1.6 mm | 2.34 mm | 3.56 mm | 4.70 mm | 9.40 mm |

| Belt thickness | 2.6 mm | 3.3 mm | 4.9 mm | 7.0 mm | 12.0 mm |

| Linear dimension | 0.0043 kg/m /rib | 0.0083 kg/m /rib | 0.0190 kg/m /rib | 0.0290 kg/m /rib | 0.1100 kg/m /żebro |

| Max. belt speed/velocity | 80 m/s | 60 m/s | 55 m/s | 50 m/s | 40 m/s |

| Min. pulley diameter | 9 mm | 18 mm | 50 mm | 70 mm | 180 mm |

| Min. idler diameter | 15 mm | 40 mm | 65 mm | 120 mm | 280 mm |

| Tension | 25 do 35 N/rib /range |

35 do 50 N/rib /range |

90 do 110 N/rib /range |

135 do 200 N/rib /range |

450 do 550 N/rib /range |