Conveyor belts come with a variety of tensil member fabrics: polyester E, polyamide P, aramide-polyester AE, polyester-cotton EC, polyester-polyamide EP or aramide A , generally with polyurethane covers (U) on one or both sides , polyolefine (A), polyester(ES),polyvinyl chloride(V), rubber (G), polyamide (PA), PTFE (polytetrafluoroetylene) or silicone(SI). In our offer we also have conveyor belts made of cotton (C), felt (F) and flock(Z). For polyurethane covers you can choose from normal U cover or hardened UH cover.

Polyvinyl chloride covers come in normal version V, soft version VS or hardened version VH (in this case not oil resistant).

Most of belts are siutable to work on sliding bed or roller bed (with coating on friction side), and both drives.

Plastic belt build, properties and application

Transportation side:

- various cover materials (as above), – thicknesses and top face structures have influence on mechanical and transportation properties of belt.

Friction side:

- material type and friction side covers decide of noise emission, energy consumption and belt usability to work on slidin bed/rollers.

Tension members

The selection of proper 1,2,3 number of ply , multi-ply M or HighTech H material determinates proper belt application for knife-edges, curves or in trough and also has impact for belt working, elongation, positioning.

Belts with H (HighTech) fabric have always one ply and vary depending on tensile strength. This is why they are siutable to work on small pulley diameters (also knife-edges) with heavy loads and low elongaton.

The M fabric is siutable for heavy duty applications (damp,high abrasibility, cut ant wear) due to its special milti-ply build.

Such belts are delamination resistant. The combination of various types of fabrics, top face patterns, surfaces enables to applicate the belts for almost all industries.

Inclined transportation (incline-decline)

For inclined conveyors smooth top face pattern belts are required. Permissible incline angle depends on material carried and belt top face pattern also on outer outdoor conditions (dust, damp). Belts with special linear, lattice, grip patterns allow bigger incline angles.

Curved transportation

For curved transportation we have special belts in our offer for food and other industries. Belts come with U and V surface and are flame retardant, antistatic, with food grade certificate.

Buffering, acumulation, shifting transportation

In case of goods shifting the belt should be perfectly flat and stabile as per belt running direction. Other important properties are: lateral stiffnes, smooth, slippery and abrasion resistant surface

Process belts

Many of belts were designed for special in -line applications in such industries as: textile manufacturing for fleece cross laying machine, bakery industry for maturing and cake forming, chipboard manufacturing, in dairies for milk coagulation, in furniture manufacturing for paint shop and many more.

Depending on the requirement you can use antistatic and non-antistatic, high conducting HC, with Atex, with anti-microorganisms protection (HCCP), flame retardant, silent running, tear and wear resistant belts.

Belts for food industry (FDA, EU, HACCP)

For unwrapped food we offer belts with FDA certificate, but also in compliane with EU regulations 1935/2004 and Nr 10/2011. Those belts come with surface that protects against bakteria cumulation and are tabbed by FORBO-SIEGLING with symbole HACCP. Belts are resistant to washing under pressure. The belt edges can be closed/seald with 3 methods to gain better food safety properties. Due to such activities bakteria do not go through belt open areas or belt is not delaminating.

In our offer we have also belts with non-fray edges to keep the product carried uncontaminated with belt fabric wreckage.

For more belt information please chceck the catalogue.

Conveyor belt equipment

Additionally equipment:

- cleats

- side/lateral profiles

- side walls

- guiding wedges

- perforation

- overlays or other fittings per request

- curved belts of various tracking types

Belt splicing methods

Depending on belt type, type of product carried and working conditions there are different splicing methods: bonding, welding, mechanical fastening.

See: Splicing methods

Conveyor belt selection

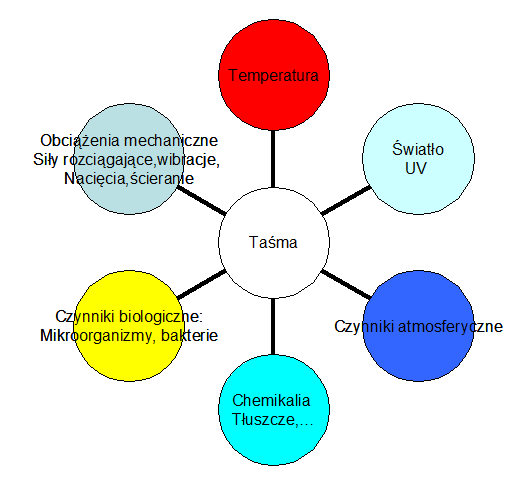

Conveyor belts are impacted by many outdoor factors such as shown for example on below plan, that have influence on belt work and wear.

Please fill out survey in case of order or inquiry for optimal belt selection.

Ankieta doboru taśmy transportującej

New AMP MISER belt series !!!

FORBO-SIEGLIN as one of a few companies introduced energy saving belts (26,5% – 39%). You can easy check the cost-saving benefits per email. Four our Customers we have channelled „cost-savings calculator“, for indicating savings capabilites according to given parameters (weight, velocity, price per kWh, etc.).

This offer is dedicated for spedition and distribution companies.At this moment those belts work on 13 international airports.

Offerd belts came with pattented anti-friction fabric coating (TXGD) on friction side.

4 types of “Amp Miser” belt series are available:

- E 8/2 TX0/V10H MT-SE-AMP black (906672)

- E 8/2 TX0/V15H LG-SE-AMP black (906673)

- E 8/2 TX0/V5H MT-AMP black (906696)

- E 8/2 TX0/V15 LG-AMP black (906697)

For many Customers energy/costs-savings are not enought arguments. For all applications, where fosile energy drives are in use, you can not only reduce the energy but also CO2 emission. Long life span and environment protection are targets for Forbo-Siegling and other companies.